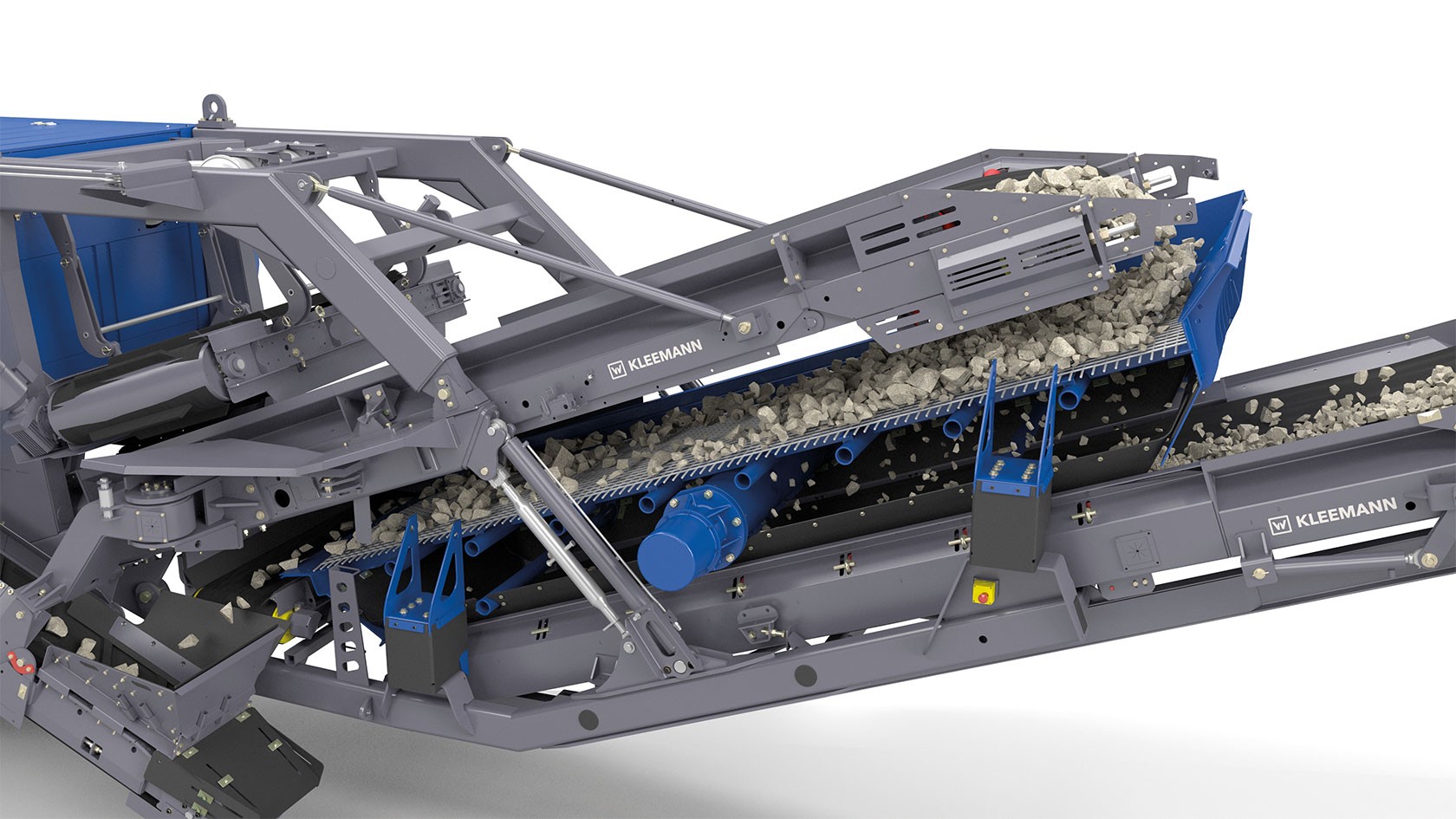

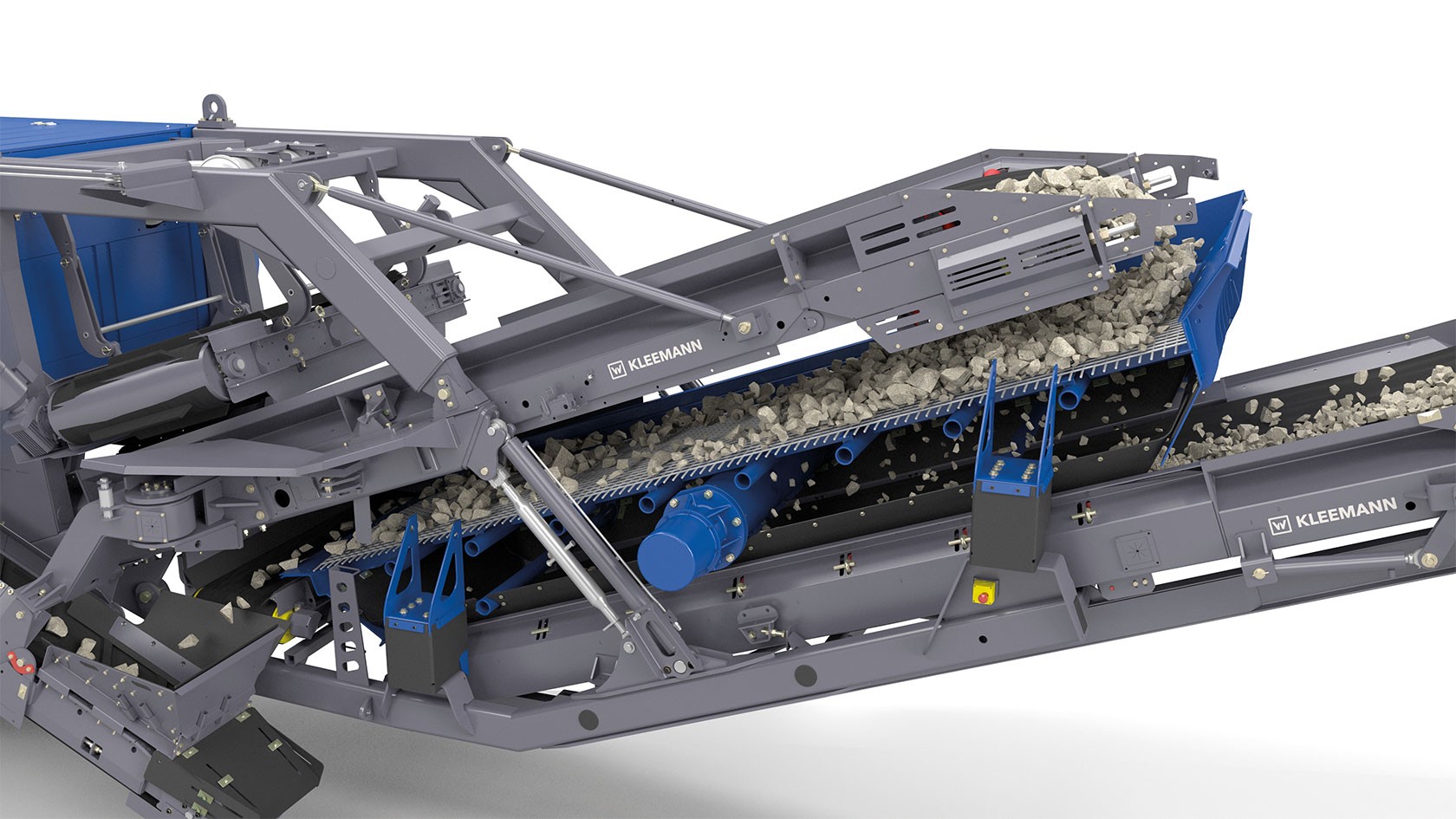

KLEEMANN Screening

Screen media face tough challenges in the course of their daily work. In order to ensure constant and reliable screening of the desired material, genuine KLEEMANN screen media must fulfil particularly stringent quality requirements.